The introduction of the laminated woven fabric has extended its demand in the market for the better deliverables, and to fulfill thereof, we present second to none quality woven fabric lamination plant that can promote you in obtaining excellent quality lamination at the high speed. The extrusion technology is the mainstay of this woven fabric lamination plant, making it renowned as an extrusion coating lamination plant in the market. The machine is suitable for laminating all types of fabric, be it PP, HDPE, woven, paperboard, aluminum without any defect. This woven fabric lamination plant has adopted by the hundreds of converting industries for laminating fabric used in making, cement bags, vegetable bags, chemical bags, salt bags, chemical bags, sugar bags, fertilizer bags, seed bags, grain bags, etc.

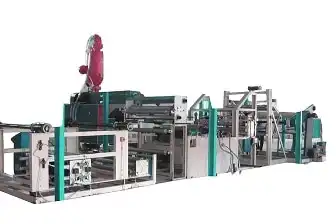

The major parts of this woven fabric lamination plant are manufactured with strict quality control in order to carry of the highest quality range of the machine that can outperform under any conditions. The lamination of the woven fabric is attained by applying melted polymer between two substrates and creating sandwich structure. The output of our woven fabric lamination plant attributes high strength and resistance against water and various gases. The machine comes with the feeder, extrusion, unwind unit, rewind unit, chilling roller, temperature roller, pressure roller, edge trimmer and PLC control system, each meets the set industry standards and hence promise for the stupendous performance. The high performance and low cost lamination ability of this woven fabric lamination machine we present in two illustrious types, mentioned as below:

PP Woven Fabric Lamination Machine

The use of the laminated PP woven fabric has reached the popularity in the market due to its ability to outlast for a longer period of time and impart notable resistance capability against water, gases and UV rays. However, the lamination need to be of best quality and that is possible with our PP woven fabric lamination machine. The highest quality components and inventive design are the grounds for its excellent performance, whereas the automatic controlling system helps prompt and accurate laminations. In order to make this lamination low cost, yet impeccable, extrusion technology is used.

The technology is hugely accepted by the industries for its considerable benefits over other lamination technologies those are failed when subjected to temperature, thanks to the strong adhesion of the melted polymer resin (PP, LDPE) that promises to outlive forever. The uniformity of the lamination and crystal clear surface imparts attractive appearance to the PP woven fabric that ultimately raises the quality quotient of the end product. We are glad to proffer such an outstanding range of the PP woven lamination plant in the manifold specification to fulfill an individual’s need. The PP woven fabric laminated by this machine is best for packaging cement, salt, chemical, fertilizer, sugar, grains and all the matters that requires excellent protection against water, gases and UV rays.

HDPE Woven Fabric Lamination Machine

HDPE laminated bags have achieved rocketing popularity due to its safe and reliable performance and hence the demand of the HDPE laminated woven fabric has increased at an edge and to fulfill such a high requirement of the industries, we are here with the most efficient range of the HDPE woven fabric lamination machine that has proven to be efficient and effective at higher speed operations. The laminations obtained through this HDPE woven fabric lamination machine shares excellent bond and hence have become magnetism in the converting industries for its ability to secure covered product from water, gases and UV rays.

This HDPE woven fabric lamination machine is designed with the utmost care towards excellence and therefore able to accomplish high quality lamination without failing. All the parts are made from the quality tested components in order to convey longevity of the machine, other than the PLC control system is appended for automatic control of the entire system and elevate the productivity of the end user. The lamination enacts by feeding the polymer granules (LDPE, PP) in the extruder, where it is melted and pushed out from the T die section and spread in the web which is used as an adhesive in case of sandwich structure, or applied as coating in case of the single side lamination.

We provide this HDPE woven fabric lamination machine in different width, capacity in order to comply miscellaneous needs of the industries. The lamination carried out by our lamination plant is finding application in making cement bags, salt bags, chemical bags, sugar bags, grain bags, seeds bags, fruit bags, vegetable bags.